Broiler production is the brightest of Nigeria's agricultural enterprises today. There exists a rapidly growing population, urbanization, and increasing demand for a low-cost source of protein in the form of chicken, such that chicken is increasingly becoming a staple Nigerian food. Yet, local output lags behind demand, offering a huge market potential for new and experienced farmers alike.This piece presents a series of straightforward steps to assist potential poultry farmers to step by step through the process and develop a profitable broiler venture in Nigeria.

Introduction: Broiler farming is a growing opportunity in Nigeria

Nigeria, which is home to more than 200 million individuals, is among the largest markets in Africa for chicken products. Urbanization, dietary modification, and the increase in a middle class have resulted in an expanding need for cheap animal protein. Of all the options, chicken is the preference option since it is cheaper than beef or mutton, grows quickly, and is widely preferred by households, hotels, and restaurants.

Frozen chicken importation is also prohibited by the government, availing opportunities for local farmers to supply fresh chicken. Nigeria is still not able to fulfill its demand for chicken even under these good conditions. This shortage is a strong case for investing in broiler farming, which can be profitable and sustainable if well undertaken.

6 Steps To Starting A Poultry Farm In Nigeria

Operationalizing a broiler farm in Nigeria presents tremendous opportunities, but with some challenges that each farmer will have to expect. From varying costs of feed and disease infection to infrastructure constraints and market volatilities, these elements can have a strong impact on profitability if poorly managed. Knowing these risks and having practical solutions is key to ensuring healthy flocks, managing costs, and maintaining consistent production.

Step 1: Market research and farm location

The first action towards starting a broiler farm in Nigeria is to learn about the market and location. Farmers must study the demand of consumers in their preferred area, identify times of peak consumption, and analyze prevailing prices. The big consumption markets are Lagos, Abuja, and Port Harcourt, but smaller towns and peri-urban centers also offer good opportunities. Proximity to market is important because moving live birds or processed chicken in long distances may add costs and losses.

Distance also impacts access to water, feed, electricity, and veterinary care. Remote areas with poor infrastructure can add the cost of production, so choosing an area with a good road network and utilities is therefore important. Carefully done market research ensures that investment is linked to local demand, and a good location for the farm provides the foundation for sustainable production.

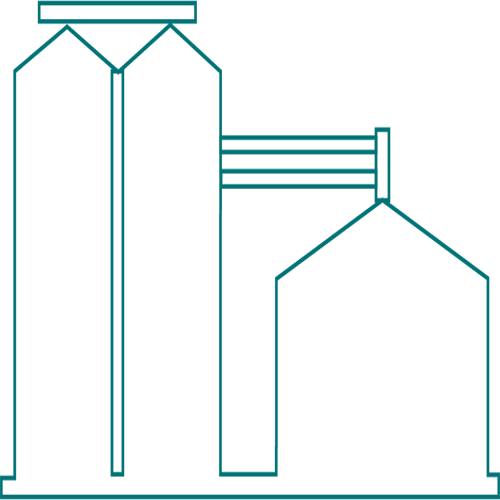

Step 2: Housing and infrastructure

After selecting a location, farmers will also have to invest in house and simple infrastructure. The broiler houses must be well ventilated, insulated against the high temperature, and have enough floor space not to overcrowd them. Heat stress is a common issue in Nigeria's tropical climate, and poorly designed houses can result in significant losses.

Simple facilities such as feeders, drinkers, lighting, and brooding equipment must be in place prior to the arrival of chicks. Sanitation amenities, including drainage systems and waste facilities, are also important to control odor and ammonia buildup. Farmers who design their homes with thrift and sanitation in mind have lower mortality and better growth rates, laying the foundation for profitable ventures.

Step 3: Day-old chick procurement

The success of a broiler farm is highly reliant on the quality of day-old chicks. Farmers should buy from trusted hatcheries that have a reputation of proper health standards and proper vaccinations. Uniform, healthy chicks develop uniformly and reduce the risk of irregular performance towards the cycle.

Transportation must also be treated with care because stress during delivery weakens the birds. Before the arrival of the chicks, the brooder house should be ready with proper temperature, fresh water, and clean litter. Proper care at the early stage is a guarantee of the birds adapting quickly and getting a healthy start, which is key in profitability.

Step 4: Feeding and nutrition

Broilers feeding is also the most costly aspect of broiler production, with its cost often as much as 60 percent of all costs. Maize and soybean meal price hikes have transformed feeding into one of Nigeria's biggest challenges facing farmers. Special feeds must be consumed by broilers at every stage of growth, such as starter and grower and finisher rations. The nutritional content of the feed directly affects weight gain, while losses may be due to improper storage or contamination. To increase efficiency, some farmers utilize broiler growth enhancer that enhance birds' nutrient use.

A product like Lima-Biotech's Broilers Growth Promoter can be of gigantic value at this stage by increasing feed conversion ratios, allowing for the birds to reach market weight on less feed. This not only reduces the cost per kilogram of meat produced but also eliminates the economic strain incurred through costly feeds, which are still the major setback in Nigeria's poultry sub-sector.

Step 5: Health management and biosecurity

Disease management is also a top priority in broiler production. Outbreaks of Newcastle disease, Gumboro, or respiratory diseases have devastated the production for countless Nigerian farmers. A strict vaccination regime and veterinary guidance are not choices but must be supported by first-rate biosecurity. Restricting visits to the farm, equipment decontamination, and control of rodents and free-ranging wild birds will go a considerable distance to prevent exposure to pathogens. Producers also need to fight off environmental stressors such as heat and air pollution, which reduce disease resistance.

On this score, Lima-Biotech's Broilers Growth Promoter enhances value by stimulating gut health and immunity development, which makes birds resistant to stress and minimizes mortality rates. This reduces the application of antibiotics and renders growth more uniform, improving flock performance and profitability.

Step 6: Harvesting and marketing

Nigerian broilers take between five to seven weeks to reach market weight, depending on breed, quality of feeds, and overall management. Harvest timing is critical as holding beyond the optimal time only increases costs with minimal weight gain. Marketing systems are highly varied, ranging from the sale of live birds at local markets to supplying restaurants, hotels, and supermarkets with processed chicken. Direct retail sales generally yield higher margins, and holiday seasons provide a higher profitability margin. Building trust with customers through regular delivery of healthy, well-groomed birds ensures repeat sales and establishes market share.

Address common challenges with practical solutions

Nigerian broiler producers have recurring problems that can jeopardize profitability if not properly managed. The most severe is feed cost, and this can best be overcome through efficient feeding and storage. Disease outbreaks are always present, but good biosecurity and preventive measures can go a long way in minimizing losses. Bad roads, unsteady power supply, and absence of water bring further stress, but farmers generally manage this by investing in stand-by power or placing farms near stable supplies. Market volatility is also common, with seasonal and regional levels of availability driving price variations. Farmers who stagger cycles of production to coordinate with peak demand as well as those who have direct market relationships tend to survive these shocks.

Conclusion: Broiler farming can be extremely rewarding in Nigeria

Nigerian broiler production is an opportunity as well as a challenge. There is growing demand for chicken, assisted by changes in dietary habits and population growth, but government restrictions on imports provide support to domestic farmers. Profitability, however, requires ideal control of feed, housing, health, and marketing. Strategic use of supportive products like Lima-Biotech's Broilers Growth Promoter helps farmers overcome two of the biggest challenges—feed expense and disease-related mortality—through enhanced efficiency and flock hardness. With proper planning and self-discipline in follow-through, broiler rearing can be a sustainable and rewarding enterprise that promotes food security and economic development in Nigeria.

- About Lima Biotech

- Careers-Lima Biotech

- Code of Conduct-Lima Biotech

- Conditions of Sale-Lima Biotech

- Contact-Lima Biotech

- Cookies Policy-Lima Biotech

- Find Agent-Lima Biotech

- Global Warehouses

- Investor Relations-Lima Biotech

- Legal Information-Lima Biotech

- Privacy Policy-Lima Biotech

- Success-Lima Biotech

- Sustainability-Lima Biotech

- World Class Manufacturing-Lima Biotech