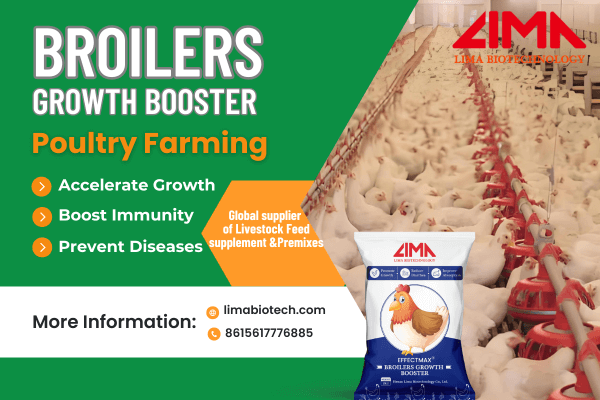

Amidst intensifying competition in the poultry farming industry, broiler producers face multiple pressures and challenges. Persistently high feed costs, increasingly stringent consumer demands for meat safety, and extended production cycles leading to cash flow difficulties are continuously squeezing profit margins. Broiler growth enhancers have emerged as a critical solution to these pain points, becoming an essential requirement in modern broiler farming. They effectively help farmers precisely enhance growth performance while reducing costs and increasing efficiency.

Why has the broiler growth enhancer become an essential requirement for farming?

For broiler farmers, "boosting efficiency, reducing costs, and ensuring safety" remain core objectives. Yet in practice, multiple challenges make achieving these goals difficult.

From a cost structure perspective, feed expenses account for 60%-70% of total broiler farming costs, representing the largest expenditure for farmers. Yet under traditional farming models, broilers absorb only 65%-75% of nutrients like protein and amino acids from feed. Unutilized nutrients are excreted in feces, causing waste and fermenting in the gut to produce harmful substances that compromise intestinal health. Simultaneously, broiler chickens possess underdeveloped intestinal functions. In high-density farming environments, pathogenic microorganisms like E. coli and Salmonella readily proliferate. Combined with stressors such as temperature fluctuations, flock transfers, and vaccinations, the incidence of intestinal diseases remains persistently high. Statistics indicate that intestinal issues can reduce broiler survival rates by 5%-10% and decrease weight gain by 15%-20%.

Broiler farms employing scientific management and premium Growth Boosters can effectively reduce feed conversion ratios and shorten production cycles. Utilizing Broiler Growth Promoters effectively improves gut health, enhances feed conversion efficiency, and boosts immunity. This approach precisely addresses core challenges in broiler farming, serving as the key to breaking through production bottlenecks and enhancing profitability.

Four Core Functions of Broiler Growth Booster

Broiler growth enhancers are not single-component products but rather synergistic blends of functional ingredients including probiotics, prebiotics, enzymes, organic acids, and plant extracts. Through coordinated action, they enhance broiler growth performance across multiple dimensions, summarized in four core functions:

1. Regulating Gut Microbiota

The gut serves as the primary site for nutrient digestion and absorption in broilers, while also functioning as the body's largest immune organ. Gut health directly determines growth efficiency. Probiotics (such as Bacillus, Lactobacillus, and yeast) and prebiotics (such as oligosaccharides and inulin) in high-quality growth enhancers operate in a synergistic mode: Probiotics competitively inhibit harmful bacteria from adhering to the intestinal mucosa, reducing toxin production. Simultaneously, they secrete organic acids like lactic acid and acetic acid, lowering intestinal pH to further suppress harmful bacterial proliferation. Prebiotics serve as an energy source for probiotics, promoting the proliferation of beneficial bacteria and extending their colonization time within the gut.

This synergistic action protects the integrity of the broiler's intestinal mucosa, increases secretion of digestive enzymes (protease, amylase, lipase), and boosts nutrient absorption rates by 10%-15%. This fundamentally reduces nutrient wastage, laying a solid foundation for subsequent growth.

2. Supplementing with high-efficiency enzyme preparations significantly reduces feed conversion ratio

Components like phytate and non-starch polysaccharides in feed act as "roadblocks" hindering nutrient absorption in broilers. Phytic acid binds with nutrients like phosphorus, calcium, and amino acids, forming poorly absorbable complexes. Non-starch polysaccharides increase intestinal chyme viscosity, hindering nutrient contact with the intestinal mucosa. Enzymes in growth promoters specifically address these issues.

Phytase effectively breaks down phytate, releasing chelated phosphorus, amino acids, and other nutrients. This not only enhances phosphorus utilization but also reduces the need for inorganic phosphorus supplementation, thereby lowering production costs and environmental pollution. Non-starch polysaccharide enzymes like xylanase and β-glucanase break down cellulose and hemicellulose in feed, reducing intestinal bolus viscosity and improving intestinal motility. Practical experience shows that adding enzyme preparations to broiler feed can increase feed conversion efficiency by 8%-12%, saving feed costs of 0.5-1 yuan per broiler, yielding significant economic benefits.

3. Enhancing Immunity to Reduce Disease and Antibiotic Use

Broilers exhibit rapid growth and vigorous metabolism, yet possess relatively weak immunity, making them susceptible to pathogenic microorganisms and stress factors. Organic acids and plant extracts in growth promoters serve as natural defenses to enhance broiler immunity.

Organic acids exhibit broad-spectrum antibacterial effects, directly eliminating or inhibiting harmful bacteria in the gut to reduce disease risks. Active components in plant extracts not only combat bacteria and viruses but also stimulate the development of immune organs like the thymus, spleen, and bursa of Fabricius, enhancing lymphocyte proliferation and antibody levels. Long-term use can increase broiler survival rates by 5%-8% while reducing antibiotic usage, aligning with current industry trends toward antibiotic-free farming and ensuring meat safety.

4. Alleviating Stress Responses to Ensure Stable Growth

During rearing, broilers inevitably encounter stressors like temperature fluctuations, transportation, and flock transfers. Stress elevates cortisol levels, leading to reduced feed intake, digestive dysfunction, and weakened immunity—severely impacting growth performance. Components in Broiler Growth Promoter—including Vitamin C, Vitamin E, electrolytes, and betaine—effectively mitigate stress.

Vitamins C and E, acting as antioxidants, neutralize free radicals generated during stress, protect cells from oxidative damage, and maintain normal physiological functions. During heat stress, broilers lose significant amounts of water and electrolytes through respiration and excretion. Electrolyte supplementation rapidly restores fluid balance and alleviates discomfort caused by heat stress. With these ingredients added, broiler feed intake reduction during stress decreases by 30%-50%, maintaining stable weight gain and preventing production losses caused by stress.

5 Key Criteria for Selecting High-Quality Broiler Growth Boosters

Core Ingredients: Prioritize scientifically formulated blends with clearly defined functions

Premium broiler growth enhancers must clearly label core ingredients, with formulations centered on critical growth needs. Ideal combinations encompass multiple functions—gut regulation, immune enhancement, and absorption promotion—including bioactive peptides, oligosaccharides, plant polysaccharides, and complex enzymes. — Bioactive peptides support immune enhancement, oligosaccharides promote beneficial bacterial proliferation, and complex enzymes optimize nutrient absorption. Only through synergistic multi-component action can critical needs like gut health, immunity, and nutrient utilization during broiler growth be comprehensively addressed, avoiding the limitations of single-component solutions.

Assessing Practical Efficacy: Focus on Three Core Objectives—Growth, Health, and Cost

When selecting products, prioritize solutions that effectively address farming challenges. Core benefits should encompass three areas: First, promoting growth to accelerate weight gain in broilers; second, safeguarding health by reducing diarrhea, disease incidence, and mortality rates while alleviating liver metabolic burden; third, optimizing costs through improved feed absorption efficiency, reduced feed waste, and decreased medication frequency. High-quality products clearly outline expected outcomes for different growth stages, enabling farmers to assess alignment with their specific needs.

Evaluate Usability: Opt for Products with Simple Operation and Strong Adaptability

A good growth promoter should feature convenient application methods that seamlessly integrate into daily farming routines without complex procedures. For example, it should support direct mixing with feed at clearly defined ratios, making it suitable for standard feed usage scenarios. Additionally, the product must be suitable for long-term use, delivering sustained efficacy to avoid increasing operational costs and management complexity due to cumbersome application methods or poor adaptability.

Storage and Shelf Life: Ensure Stability and Compatibility with Usage Cycles

Quality products clearly state storage conditions and shelf life, such as requiring dry storage, protection from rain, and resealing after opening. These details ensure the product remains stable during storage without losing active ingredients. A reasonable shelf life (e.g., 24 months) should align with farming cycles, allowing farmers to purchase as needed without frequent restocking and reducing inventory management pressure.

Evaluate Brand Standardization: Prioritize Transparent, Compliant Brands

When selecting products, verify whether the brand provides clear information on ingredients, efficacy, usage instructions, and specifications. Avoid products with ambiguous or incomplete details. Reputable brands adhere to industry standards, ensuring consistent product specifications (e.g., 2kg per bag). This facilitates precise dosage control for farmers, guarantees product quality consistency, and minimizes usage risks associated with non-compliant brands.

How to scientifically use Broiler Growth Booster?

Even with a high-quality growth promoter, improper application prevents optimal results. Farmers must master correct usage techniques and avoid common pitfalls to maximize the effectiveness of Broiler Growth Promoter.

Precise Application by Growth Stage

Broilers exhibit distinct physiological characteristics and nutritional requirements at different growth stages, necessitating "demand-based adjustments" for growth promoter usage:

- Nursery Stage (1-14 days): At this stage, broilers have weak intestinal function and low immunity, making them susceptible to pathogenic microorganisms. Growth promoters primarily containing probiotics and organic acids should be selected. The focus should be on improving the intestinal micro-ecological environment, enhancing immunity, and reducing chick mortality.

- Early Fattening Stage (15-28 days): As growth accelerates and nutritional demands surge, employ products centered on enzyme preparations and prebiotics. This enhances feed digestion and absorption rates, laying the foundation for subsequent fattening.

- Late Fattening Stage (29 days to market): This is the critical period for broiler weight gain, requiring focused promotion of muscle development and body weight increase. Growth promoters primarily containing plant extracts and amino acid chelates are recommended to enhance metabolic function, increase market weight, and improve meat quality.

Strictly Control Additive Dosage

Some farmers mistakenly believe that "higher additive doses yield better results." In reality, excessive growth promoters not only increase production costs but may also adversely affect broilers. For instance, excessive organic acids can lower intestinal pH, inhibiting digestive enzyme activity, while excessive probiotics may disrupt intestinal flora balance and cause digestive disorders.

Therefore, strictly adhere to the recommended dosage in the product instructions and avoid arbitrary adjustments. In special circumstances (such as high-temperature/high-humidity seasons or disease outbreaks), dosage may be appropriately adjusted under the guidance of the manufacturer's technical personnel. For instance, increasing the addition of organic acids and electrolytes can enhance broilers' stress resistance and disease resistance.

Proper Mixing to Ensure Uniformity

The uniformity of growth promoter mixing directly impacts efficacy. Inadequate mixing may result in some broilers receiving excessive doses while others receive insufficient amounts, leading to significant variations in growth performance. The correct mixing method follows the "premix first, then total mix" principle:

- Premix stage: First mix the growth promoter thoroughly with a small amount of neutral carrier (e.g., corn flour, bran) to create a premix. The carrier quantity is typically 5-10 times that of the growth promoter to ensure even dispersion of active ingredients.

- Total Mixing Stage: Incorporate the premix into the complete feed using a feed mixer. Mixing duration depends on equipment type and capacity, typically 5-10 minutes, ensuring the coefficient of variation for uniformity does not exceed 7%.

Simultaneously, avoid mixing with incompatible substances: Probiotic products should not be used concurrently with antibiotics (e.g., penicillin, cephalosporins). If antibiotics are necessary, maintain a 2-3 day interval to prevent antibiotic destruction of probiotics. Enzyme preparations should avoid contact with high temperatures, strong acids, or strong alkalis to prevent enzyme inactivation.

Combined with Scientific Farm Management

Even with high-quality Growth Boosters, suboptimal results may occur under poor farming conditions, nutritionally imbalanced feed, or lax management practices. Therefore, farmers must implement the following management measures:

- Ensure balanced feed nutrition: Formulate feed with appropriate levels of protein, energy, vitamins, and minerals according to the specific needs of broilers at different growth stages, providing the "nutritional foundation" for growth promoters to function effectively.

- Optimize the farming environment: Maintain appropriate temperatures (32-35°C during the brooding period, 20-25°C later) and humidity (50%-60%) in the chicken house. Ensure regular ventilation to reduce concentrations of harmful gases such as ammonia and hydrogen sulfide. Promptly remove manure and perform regular disinfection to minimize the proliferation of pathogenic microorganisms.

- Maintain optimal stocking density: During the brooding phase, maintain a density of 20–25 birds per square meter; during the fattening phase, maintain 10–15 birds per square meter. Avoid excessive density to prevent stress, uneven feed intake, and disease transmission among broilers.

- Regularly monitor growth performance: Weigh broilers weekly and record metrics such as feed intake, feed conversion ratio, and survival rate. Adjust growth promoter usage protocols and farming management practices promptly based on monitoring results to maximize farming profitability.

Why Choose Lima Biotech Growth Booster for Broilers?

Scientifically Formulated for Multi-Functional Synergy Addressing Core Farming Needs

Lima Biotech Broiler Growth Promoter (EffectMax® Series) employs a meticulously formulated blend containing core ingredients like bioactive peptides, oligosaccharides, plant polysaccharides, and complex enzymes. This achieves synergistic multi-functional benefits: Bioactive peptides and plant polysaccharides enhance broiler immunity, boost phagocyte function, and reduce disease incidence; Oligosaccharides maintain gut microbiota balance, promote beneficial bacteria proliferation, effectively reduce diarrhea incidence, and improve intestinal microecology; Complex enzymes enhance feed nutrient absorption, minimize feed wastage, and protect broiler growth from multiple dimensions, comprehensively addressing the three major farming challenges: weight gain, health, and cost.

Clear Effects Deliver Tangible Farming Value at Each Stage

Product efficacy is clearly observable by stage: Short-term (3-7 days): Improves feed absorption efficiency, reduces feed excretion, resolves nutritional diarrhea, and promotes well-formed droppings; By mid-stage (14 days), it significantly boosts broiler survival rates, reducing early-stage losses. During the chick-rearing phase, it promotes glossy toe scales and vibrant feather coloration, providing visible indicators of health. In the fattening phase, it continuously regulates the intestinal environment, further enhancing feed utilization while strengthening stress resistance. This reduces medication use and delivers tangible, perceptible profit increases for farmers.

Convenient and user-friendly, seamlessly integrated into daily farming routines

Product application is simple and efficient: merely mix 2kg of product evenly with 1000kg of feed—no additional complex operations are required, making it perfectly suited for routine feed distribution scenarios. It also supports long-term use, delivering sustained efficacy without increasing operational burdens. Whether in small-scale farms or large breeding bases, it seamlessly integrates into daily management, lowering usage barriers.

Stable Storage Ensures Long-Term Quality

Lima Biotech clearly specifies storage requirements (dry location, protected from rain, reseal after opening) to prevent moisture damage and ensure active ingredient integrity during storage. The 24-month shelf life aligns with most broiler production cycles, allowing farmers flexible procurement based on needs. This eliminates short-term expiration concerns, simplifies inventory management, and guarantees consistent quality over extended use.

- About Lima Biotech

- Careers-Lima Biotech

- Code of Conduct-Lima Biotech

- Conditions of Sale-Lima Biotech

- Contact-Lima Biotech

- Cookies Policy-Lima Biotech

- Find Agent-Lima Biotech

- Global Warehouses

- Investor Relations-Lima Biotech

- Legal Information-Lima Biotech

- Privacy Policy-Lima Biotech

- Success-Lima Biotech

- Sustainability-Lima Biotech

- World Class Manufacturing-Lima Biotech